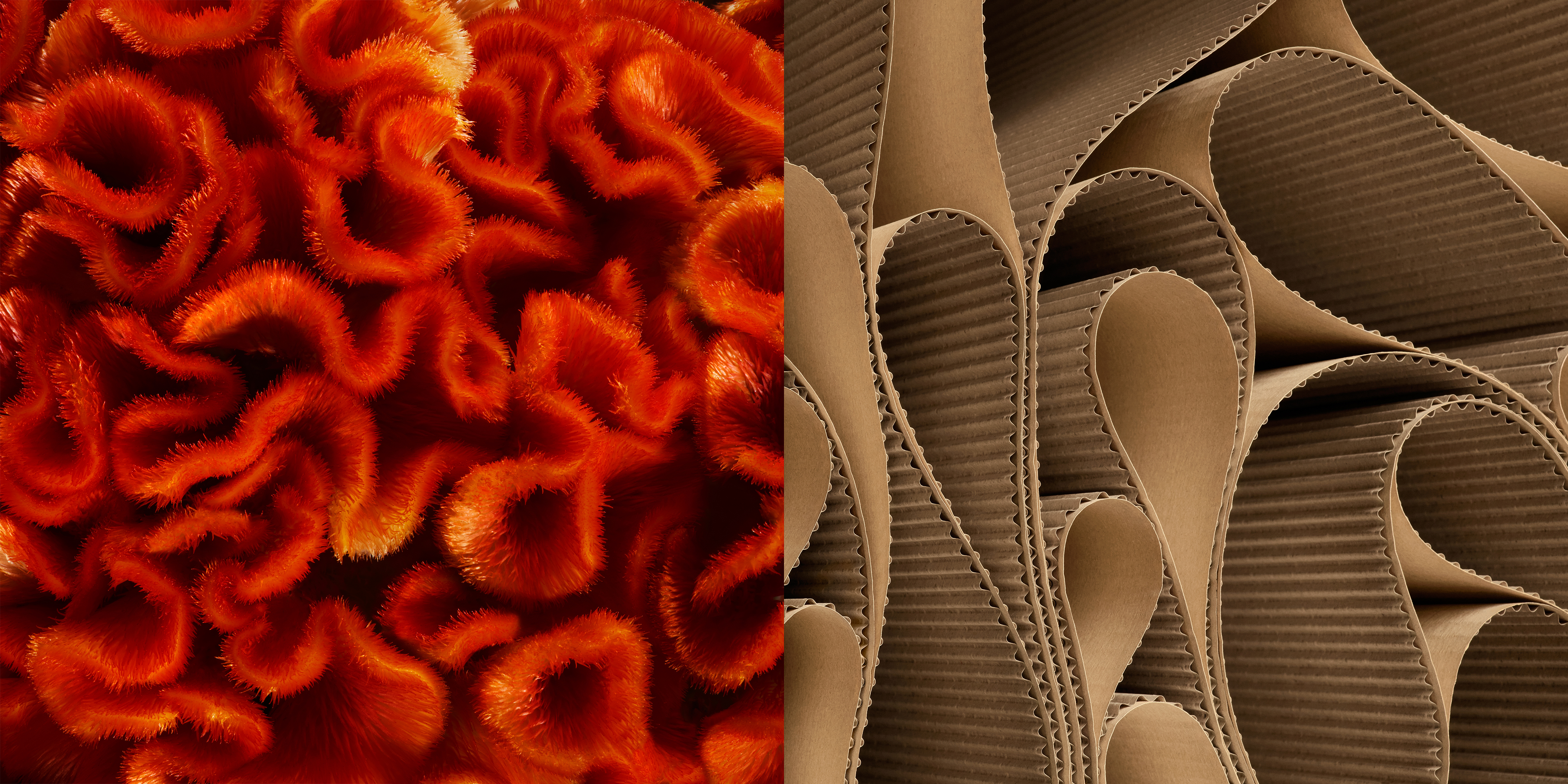

Environment

Everything is connected to everything and we see the links in-between.

The awareness of closing gaps

Closed material cycles are the key to climate neutrality. We do our best to recycle as much recovered paper as possible.

We always use recycled fibre wherever possible, playing our part in protecting our forests. If we cannot avoid the use of virgin fibre, we purchase it from FSC®-certified sources. Illegal logging does not occur at any point in our supply chain, and damaging chemicals are not used at any stage.

In terms of logistics, we avoid journeys with empty lorries. We use water in a circular fashion and our paper factories have their own wastewater treatment plants. We collect used packaging from our customers, recycle it and turn it into new packaging.

Our ambition and goals

As little packaging as possible

But as much as necessary. Unlike other materials such as plastic, our board and corrugated card mean that goods can be wrapped in eco-friendly packaging.

There is no doubt that the manufacture of cardboard is a high-energy and water-intensive process.

We handle resources carefully and efficiently – and not just in terms of energy, the climate, waste, and water. We investigate issues such as deforestation, soil erosion, and illegal logging when procuring raw materials.

- By 2030, we will have reduced our resource consumption per tonne of paper, corrugated card, and cardboard produced by 10%.

- Scope 1 and 2 GHG (greenhouse gas) emissions from paper mills reduced by 22.9 % per ton of paper produced by 2030 from a 2017 base year.*

- Scope 1 and 2 GHG emissions from packaging activity reduced by 32.5 % by 2030 from a 2017 base year.*

- Scope 3 GHG emissions reduced by 26 % per ton of paper and board produced by 2030 from a 2017 base year.*

*The target boundary includes biogenic emissions and removals from bioenergy feedstocks

To reach these goals, we will optimize our fibre recovery process, improve our logistics and introduce new technology along the value chain.